The main problems found with the Long Lee-Enfield and Lee-Metford rifles during the 2nd Boar War (1899-1902) were their length, especially for cavalry, and the lack of charger loading. The latter was a distinct disadvantage when facing the Boars armed with Model 1895 Mauser rifles that could be reloaded quickly via stripper clips.

Work started in 1900 on the development of a lighter and shorter rifle suitable for both cavalry and infantry and early models were subject to trials during the Boar War. The most troublesome aspect of the shortened rifle was charger loading. In January 1901, manufacture was approved for 1000 shortened Lee-Enfield rifles. Half the rifles were fitted with an Enfield experimental backsight and the other half with a backsight approved by the Small Arms Committee. The former was similar to the sight eventually accepted and the latter was a leaf sight similar to that on the Magazine Lee-Enfield rifle or MLE.

Using the same rifling as the MLE, gave a significantly lower muzzle velocity in the shortened rifle. The rifling was therefore modified to be deeper at the muzzle and about 1 thousandth of an inch shallower towards the breech. In this way the muzzle velocity was raised to 2010 – 2030 fps which was not that far off from an MLE.

These 1000 shortened Lee-Enfield rifles were subjected to comprehensive trials among the infantry regiments, the cavalry and the Royal Marines. Overall, the shortened rifles were well received by the service units taking part in the trials and in December 1902 the Short Magazine Lee-Enfield Rifle Mk I was approved for service for both cavalry and infantry.

Short Magazine Lee-Enfield Rifle Mk I

The Short Magazine Lee-Enfield or SMLE was over 1 lb lighter than the MLE it replaced and 5 inches shorter with a barrel length shortened from 30.2 inches to 25. 2 inches. It was produced at the Royal Small Arms Factory (RSAF) Enfield, the Birmingham Small Arms (BSA) and London Small Arms (LSA) factories.

The main change compared with the MLE was the fitting of a hand guard that completely enclosed the barrel to protect the firer during extended firing. The SMLE was fitted with a long nose cap extending almost to the end of the barrel providing curved ear protectors for the front sight and a piling swivel underneath at the rear. Just forward of this swivel was a lug for the Pattern 1903 bayonet which was similar to the Pattern 1888 bayonet but with a modified quillon ring to engage with a cylindrical boss on the nose cap just under the muzzle of the barrel.

The hand guard consisted of three parts and was designed to provide clearance for the barrel. The long upper hand guard slotted into the nose cap at the front. The nose cap was attached to the full length lower hand guard at the front via screws to hold it in place and, along with the long upper hand guard, was held in place further back by the mid band to which was attached the upper sling swivel. As with the MLE, there was a shorter upper hand guard held in place by barrel clips between the backsight and the knox form.

The front sight was attached to the barrel by a collar that was pinned in place. The sight used a barleycorn post mounted in a dovetailed slot in order to be able to adjust its position for sighting. The sight was available in three heights differing by .015 inches to allow the sighting to be corrected before the rifle was issued. The backsight leaf was pivoted to the bed at the front with a V-notch provided at the back. The bed had curved sides and the correct elevation achieved by moving the slide with the leaf graduated between 200 and 2000 yds. The back sight was protected by small steel wings fixed to the upper short hand guard. The Mk I SMLE was still fitted with long range volley sights that were graduated from 1600 to 2800 yds.

The SMLE Mk I was fitted with a 10-round magazine and was filled by means of 5-round chargers (stripper clips). Guides for the chargers were provided on the bolt head and on the left-hand side of the receiver. The guides were in the correct position when the bolt was fully withdrawn and allowed each set of five rounds to be pushed into the magazine using the thumb from the right hand. The left hand side of the receiver was slightly cut away to allow clearance for the thumb.

Short Magazine Lee-Enfield Mk I*

The butt stock was similar to the MLE but used a steel butt plate with no trap provided. It came in three separate lengths, one being 1/2 inch shorter than the standard and the other one being 1/2 inch longer. As with the MLE, a lower swing swivel was screwed into the bottom of the butt. The butt also had a brass marking disc recessed into the right-hand side.

The SMLE Mk I issued to the Army was not fitted with a magazine cut-off although the version provided for the Navy did have one. The bolt cocking piece was shorter than on the MLE because the safety catch was moved from the bolt to the left side of the receiver using the same pivot as the long range aperture sight. The trigger mechanism was similar to that of the MLE with the main change being to a two stage trigger. This was achieved via two separate ribs or nibs on the trigger which bore in succession on the lower arm of the sear. The weight of the first pull was 3 – 4 lb while the second pull was 5 – 6 lb.

The SMLE Mk I rifle was intended to fire the round nosed Mk II .303 cartridge with the soft nosed and hollow point Mk’s III, IV and V effectively outlawed by the 1899 Hague Convention other than for target shooting. However, in 1904, the Cordite S. A. Ball Cartridge Mk VI was introduced for use. It was similar to the Mk II but with a different distribution of metal in the cupro-nickel jacket and in the bullet itself.

A few months after the introduction of the Mk I, a windage adjustment was added to the backsight together with a number of other small modifications. The Mk I was re-introduced in September 1903.

Short Magazine Lee-Enfield Rifle Mk I*

In July 1906, the Short Magazine Lee-Enfield Rifle Mk I* was introduced into service and included modifications that resulted after extensive trials with troops. Most Mk I* rifles were produced at RSAF Enfield but some were also produced at RSAF Sparkbrook and at BSA.

In the Mk I*, the butt plate was changed to gunmetal and a trap fitted for insertion of an oil bottle and pull-through. The butt was recessed to take a small bracket for the sling swivel. The magazine was lengthened at the front to facilitate easier charger loading. There were other minor changes to the swivel screws and to the striker keeper screw.

The magazine cut-off was re-introduced for safety reasons. Originally, this was used with the MLM and MLE rifles when volley fire was the norm and the rifles were used mainly for single round firing . The cut-off allowed for the magazine capacity to be kept in reserve. However, with the charger loading of the SMLE Mk I, and when independent rifle fire was then the norm following the 2nd Boar War, the use of the cut-off for single round firing was no longer used operationally. This is why it was not fitted to the Mk I originally. However, it was then found that the use of the new safety catch did not always render the weapon entirely safe on active service.

In order to overcome some of the problems found, the magazine cut-off was re-introduced in the SMLE Mk I* (the Mk I had provision for it but it was simply not fitted on infantry rifles). To make the weapon completely safe when the soldiers were not engaged with the enemy, it was necessary to close the magazine cut-off, cycle the bolt to remove any cartridge in the breech and then to close the bolt and apply the safety catch. In modern British Army parlance, this procedure would have corresponded to being ordered to MAKE SAFE the weapon although this command did not exist in the British Army at the time the SMLE was introduced.

Short Magazine Lee-Enfield Rifle Mk II/ Mk II*

A number of MLM’s and MLE’s were converted to either SMLE Mk I or Mk I* standard to give the SMLE Mk II and Mk II* standards, respectively.

Cartridge SAA Ball .303 Mk VII

As a result of the 1899 Hague Convention, the use of .303 Mk II – V cartridges were confined to target practice after 1899. However, in order to comply with this convention, the Mk VI was introduced in 1904 which was effectively a Mk II with a thinner cupro-nickel jacket to increase its lethality.

The Mk VI cartridge was not that effective and in the meantime both France and Germany had adopted the use of pointed, so-called, Spitzer bullets which significantly increased the bullets muzzle velocity, flattening its trajectory. Both the French and German Spitzer bullets were boat tailed. However, a straight sided pointed bullet was adopted in 1910 for the SMLE referred to as the Cartridge S.A. Ball .303 inch Cordite Mark VII giving a muzzle velocity of 2440 fps.

The Mk VII used a 174 gr full metal jacket bullet in which the front half of the core was made of aluminum and the rear half of conventional lead and antimony alloy. The effect of moving the centre of gravity backwards resulted in the bullet tumbling when it hit a soft target greatly increasing its destructive power. Despite being designed to cause severe wounds like the Mk III – VI bullets, the design of the Mk VII was deemed to be compatible with the 1899 Hague Convention since this only covered bullets that expanded or flattened on impact.

Short Magazine Lee-Enfield Rifle Mk III

The charger loading system used in the Mk I and Mk II rifles using a guide on the bolt head was not really satisfactory. Therefore, in January 1907, the Short Magazine Lee-Enfield Rifle Mk III was introduced which used a new bridge charger guide. The slots for the charger stops were sloped forward so that, after the cartridges were pushed into magazine, closing the bolt ejected the empty charger. As well as being manufactured in the UK, the Mk III was also manufactured in India (Isaphore) and Australia (Lithgow).

Other changes included a U-notch in the back sight instead of the original V-notch. The front sight was replaced by a straight edged blade. In addition, it was fitted with modified foresight protectors. A butt plate was fitted with a trap to allow an oil bottle and pull-thought to be housed in the butt.

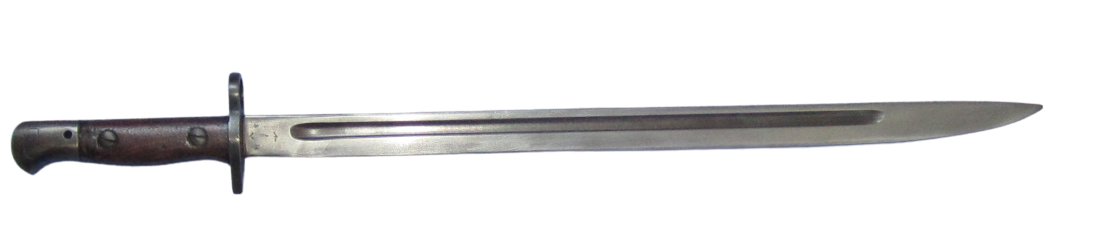

The SMLE Mk III was fitted with the Pattern 1907 sword bayonet that had a one sided blade 17″ long with a shallow fuller 12 inches long on either side. The original Pattern 1903 bayonet was considered to be too short with the shortened rifle and, when a longer replacement was investigated, a design was produced based on the Japanese Arisaka bayonet. Originally, the bayonet was fitted with a hooked lower quillon but this was later deemed to be impractical and removed. With the Pattern 1907 bayonet fitted, the SMLE Mk III was then of similar overall length to the MLM and MLE with the Pattern 1888 bayonet fitted (~5 ft 2 in).

Short Magazine Lee-Enfield Rifle Mk III*

In 1915, a number of changes were made to simplify manufacture of the SMLE during the First World War resulting in the Short Magazine Lee-Enfield Rifle Mk III* which, nevertheless, was not officially approved until 1916.

The main changes in the Mk III* were the omission of the magazine cut off, the omission of the volley sights, the omission of the butt disk and the omission of the windage adjustment on the backsight. However, since the Mk III* was intended to economise on manufacturing, not all the omissions were made; for example, some Mk III* rifles are found with magazine cut offs.

Short Magazine Lee-Enfield Rifle Mk IV

In June 1907, a pattern was sealed governing the conversion of a number of MLM Mk II/II* and MLE Mk I/I* rifles to SMLE Mk III standard. These rifles became the Short Magazine Lee-Enfield Rifle Mk IV.

Short Magazine Lee-Enfield Rifle Mk V

After WW1, work was carried out to develop an improved bolt action rifle. This led to the introduction in 1922 of the Short Magazine Lee-Enfield Rifle Mk V which went into limited production but never issued for general service use.

The main shortcoming addressed in the Mk II* was the short sight radius and the difficulty of snap shooting with leaf sight. To remedy this, the Mk V used an aperture rear sight mounted at the rear of the receiver. In addition, the Mk V incorporated an additional band at the rear of the nose cap in order to strengthen the bayonet fitting. This additional band then supported the piling swivel.

Short Magazine Lee-Enfield Rifle Mk VI

In 1926, the nomenclature changed and the SMLE Mk III became the Rifle No 1 Mk III, the Mk II*, the Rifle No 1 Mk III*, etc.

The last mark of the No 1 rifle was the Mk VI in 1930 which was another experimental model. It was designed to simply manufacture and incorporated, for example, a slab sided receiver. This mark effectively paved the way for the Lee-Enfield No 4 rifle in 1941.

My Short Magazine Lee-Enfield Rifle Mk III*

My Mk III* was made at RSAF Enfield in 1916 and is in very good deactivated condition. This was the first historic firearm that I bought many years ago and started my interest in collecting militaria.

My Mk III* was deactivated pre-2016 and is therefore referred to as Old Spec. Unlike, the later EU Firearms Directive (New Spec), my Mk III* will dry fire after operating the bolt. Under the New Spec, the sear has to be ground away so that it does not engage with the trigger.

SMLE Mk III Specifications

- Weight: 8 lb 10.5 oz

- Weight of Full magazine: 13 oz

- Weight of Bayonet: 14.5 oz

- Length of Rifle: 3 ft 8.5 in

- Length with Bayonet: 5 ft 25 in

- Length of Barrel: 25.2 in

- Calibre: .303 in

- Rifling: Enfield Segmental

- Bullet: 174 gr Mk VI round nosed bullet up to 1910

- Bullet: 174 gr Mk VII pointed bullet from 1910

- Muzzle Velocity: 2440 fps (.303 Mk VII)

- Front Sight: Blade

- Rear Sight: Rectangular notch

- Rear Sight Leaf: 200 to 2000 yds

- Dial Sight: 1600 – 2800 yds

- No. of Grooves: 5

- Depths of Grooves: .0065 in at muzzle and .00575 inch at breech

- Width of Lands: .0936 in

- Rifling Twist: Left-handed with 1 turn in 10 in

![]()