In 1926, the SMLE Mk III and III* rifles were re-designated the Rifle No. 1 Mk III and III*. The .22 rim-fire training rifle was designated as the Rifle No. 2 and the .303 Pattern 1914 rifle became the Rifle No. 3.

In 1929, a new version of the No. 1 rifle was produced, the Mk VI, that featured simplified manufacturing features, such as a flat sided receiver, although it still retained the magazine cut off. After further improvements, this model was re-designated the Rifle No. 4. A trials rifle version was then produced between 1930 – 33 for extensive trials.

Rifle No. 4 Mk I

The No. 4 Mk I was only approved for production in 1939 following the outbreak of war. It was manufactured at two new Royal Ordnance factories in Fazakerley (Liverpool) and Maltby (Yorkshire) and the new BSA factory in Shirley just outside Birmingham. However, the first war time No. 4 rifles did not become available until mid 1941. During the war, the No. 4 rifle was also made at the Canadian Long Branch plant and the US Stevens-Savage plants.

The No. 4 rifle was similar mechanically to the No. 1 rifle but with a heavier barrel. The main changes were to the design of the receiver or action body which was made stronger and with simplified features such as the change to flat sided to reduce the time and cost of manufacturing. In the production rifle, the magazine cut off was deleted. In contrast with the No. 1 rifle in which the charger bridge sides were riveted to the receiver, the charger bridge sides on the No. 4 rifle were machined as part of the receiver or action body.

The No. 4 rifle bolt was similar to that of the SMLE but the cocking piece took the form of a rimmed button. The receiver was fitted with a push down release catch behind the charger bridge to release the bolt.

The rifle butt was similar to that on the No. 1 rifle with a recessed swivel for the lower end of the rifle sling. On the No. 4 rifle, an upper and lower hand guard was used that extended to within about 2.5 inches of the end of the barrel and incorporated sheet metal end caps. The hand guard was retained by a broad band at the muzzle end and a mid band that incorporated the upper sling swivel. The rear end of the upper guard was also retained in position above the barrel knox by a barrel ring into which it slotted. The rear end of the lower hand guard had a flat steel tie plate to reinforce it.

The No. 4 Mk I rifle used a flip up Mk I aperture ladder backsight marked to 1300 yds with a fine adjustment knob. The leaf was machined from solid steel and also incorporated an aperture battle sight that could be used when the ladder sight was in the stowed position. The foresight consisted of a blade that was protected by wings. The sight block and wings were machined from solid and incorporated a barrel band that slid on to two rectangular splines machined into the barrel and was then pinned into position. The sight blade itself was a press fit into the sight block allowing its lateral position to be adjusted. Different blade heights were available to provide vertical zeroing of the rifle.

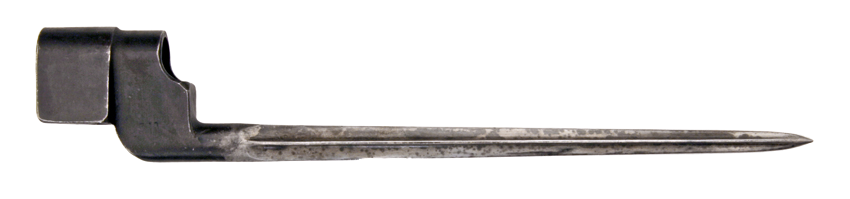

The No. 4 Mk I rifle was fitted with the Mk I spike bayonet with an 8 inch long spike. The Mk I design has a cruciform spike but manufacturing was simplified in the Mk II which had a plain round spike. The spike bayonet used a tapered tubular steel scabbard with a round stud for mounting in the frog. The bayonet fitted over the exposed end of the barrel and was held in position by latching on to two short splines machined into the end of the barrel. The bayonet needed to be rotated 45 degrees to the left to allow it to be slid over the barrel splines after which rotating it back to the normal position locked it on to the splines. The bayonet was released by operating the spring loaded catch after which it could be rotated 45 degrees and removed from the barrel.

Mk I Spike Bayonet

Mk II Spike Bayonet

Rifle No. 4 Mk I*

This No. 4 rifle version was only produced in Canada and the USA from 1942 and introduced further manufacturing simplifications. One of these was the elimination of the bolt release catch to be replaced with a cut out in the bolt head rail which enabled the bolt head to be disengaged from it allowing the bolt to be removed out the back of the rifle. The cocking piece was changed to a flat sided design with 3 grooves.

The US made Mk I* rifles originally used a simplified Mk II backsight that could be flipped between separate apertures for 300 yds and 600 yds. However, both the US and Canadian No. 4 Mk I* rifles also used the Mk II ladder sight which used a simplified sheet metal design for the leaf.

The Mk I* rifles used a a different foresight assembly to the Mk I. In the Mk I*, the barrel band consisted of just the sight block with the protection wings effectively clamping over the top of the band.

Rifle No. 4 Mk 2

The No. 4 Mk 2 was introduced after WW2 in 1949 and was intended to produce a better quality rifle free of the wartime manufacturing shortcuts. The MK 2 was made at ROF Fazakerley. The stock was changed to higher quality Walnut. The original spring loaded bolt head release was reinstated and the trigger pivot was moved from the finger guard to a new bracket attached to the front of the butt socket. The Mk 2 reverted back to the original Mk I ladder rear sight rather than the simplified wartime variants

The stock was similar to the Mk I rifles with only minor changes which included the elimination of the tie plate at the rear of the lower hand guard and its replacement by a transverse screw. This model of the No. 4 rifle was only produced at ROF Fazakerley as ROF Maltby was closed in 1949.

Bayonets

In total, there were 4 different versions of the spike bayonet (Mk I, II, II* and III) with later marks aimed at simplifying the manufacturing process.

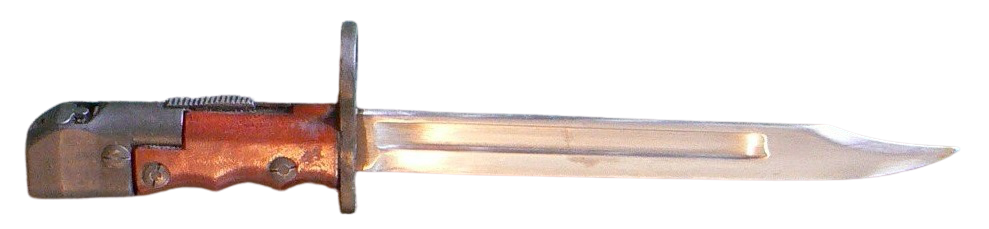

However, post-WW2, there was a strong desire to replace the spike bayonet with a blade bayonet. The first attempt was the so-called No. 7 Mk I bayonet which had a Bowie style blade with a handle and quillon with muzzle ring. The idea behind this is that it could be used as a fighting knife but, by rotating the metal end cap and latch through 180 degrees, it could be attached to the No. 4 rifle which would effectively fire through the muzzle ring. Unfortunately, this design proved to be unsatisfactory as it was found that, if the bayonet not properly fitted to the barrel, bullets could then strike the muzzle ring creating safety concerns.

A better design was produced in 1947 in the form of the No. 9 Mk I with a similar blade to the No. 5 bayonet Mk I bayonet fitted to the Lee-Enfield No. 5 rifle. In fact, the No. 9 bayonet used the same scabbard as the No. 5 bayonet.

No. 7 Mk I Bayonet

No. 9 Mk I Bayonet

Rifle No. 4 Mk 1/2 & 1/3

When the No. 4 Mk 2 rifle was introduced, existing stocks of Mk I and Mk I* rifles were refurbished to a similar standard and re-designated Mk 1/2 and Mk 1/3, respectively. The Mk 1/2 were mainly converted at ROF Fazakerley with a few at ROF Shirley. The Mk 1/3 were converted at ROF Fazakerley.

Rifle No. 4 Mk I (T) & Mk I* (T)

The sniper version of the No. 4 rifle was introduced in 1942 to replace the Pattern 1914 sniper rifle then in service. The Mk I (T) was produced at RSAF Enfield and utilised the No. 32 Mk I telescopic sight with x 3.5 magnification. The No. 4 Mk I* (T) was produced in Canada at Long Branch.

The No. 4 sniper rifle was produced using specially selected No. 4 rifles showing increased accuracy. The sighting telescope was mounted on removable bracket screwed into the left-hand side of the receiver. A butt cheek was added to aid accurate long range shooting.

The Mk I (T) continued to be used by the British Army and, in 1970, was converted at RSAF Enfield to fire the NATO standard 7.62 x 51 mm round. At this point the designation changed to L42A1. The L42A1 continued in service until 1985 when it was replaced by the L96A1 Accuracy International PM (Precision Marksman).

My No. 4 Mk I* Rifle

My Mk I* was made at Long Branch in 1944 and is fitted with the Mk I ladder rear sight. It seems to be in standard condition for a Mk I* with the only obvious changes being the removal of the tie plate at the rear of the lower hand guard and its replacement by a transverse screw as per Mk 2.

Rifle No. 4 Mk I & I* Specifications

- Weight: 9 lb 1 oz

- Weight of Full magazine: 13 oz

- Weight of Bayonet: 7 oz

- Length of Rifle: 3 ft 8.5 in

- Length with Bayonet: 4 ft 4.8 in

- Length of Barrel: 25.2 in

- Calibre: .303 in

- Rifling: Enfield Segmental

- Bullet: 174 gr jacketed round nosed lead

- Muzzle Velocity: 2440 fps (.303 Mk VII)

- Front Sight: Blade

- Rear Sight: Aperture

- Rear Sight Leaf: to 1300 yds

- No. of Grooves: 5

- Depths of Grooves: .005 in

- Width of Grooves: .0936 in

- Rifling Twist: Left-handed with 1 turn in 10 in

![]()