The Snider breech loading conversion of the muzzle loading .577 Pattern 1853 Enfield rifle musket in 1866 was always considered to be a stop gap measure pending the adoption of a new smaller bore rifle. At that time, new forms of breech loading actions were emerging as were new forms of rifling. In 1866, the War Office organised a prize competition to attract new breech loading rifle designs although it did not specify the calibre.

A large number of rifles were submitted in this competition but, after examination, only nine were accepted for trials including a Henry, a Peabody and a Martini. However, no rifle met the requirements laid out in the competition and the War Office then decided to consider each of the two main component of the rifle separately; namely, the breech system and the barrel. After further considerations, it was found that the .45 calibre Henry barrel was superior to all the other competitors including the Snider barrel that was used as a control. The only real concern was the long .450 calibre cartridge that was felt to be too susceptible to damage.

A large number of breech mechanisms were considered including both breech block and bolt actions. However, after considerable trials and endurance tests, the Martini action was considered the best. In 1869, the Martini action and the Henry barrel were mated and 200 Martini-Henry rifles were assembled for troop trials. These used a straight case .450 calibre Boxer cartridge referred to as the long chamber round. However, developments in ammunition in the meantime led to the introduction of a short round carrying the same charge as the long round but using a .577/.450 bottle shaped cartridge. This cartridge allowed the length of the action body and the chamber to be considerably reduced. It was in short chamber form that the .450 Martini-Henry rifle Mk I was finally adopted for service in June 1971.

Martini Action

The Martini-Henry rifle uses a breech block that is hinged at the top rear of the action body. It was based on the American Peabody breech block design but, where the former uses an external hammer, the Martini action uses an internal striker.

The rifle is loaded by operating the under lever behind the trigger guard which drops the front of the breech block exposing the end of the barrel into which the new round is inserted. When the lever is returned to its locked position, the breech is closed and the action is cocked ready to fire. When the lever is operated again, the breech will open and the spent round will then be automatically ejected.

The internal end of the under lever consists of two horns that engage in slots either side of the breech block that cause it to pivot down at the front when the lever is lowered and to be raised and locked into the firing position when the lever is closed. The under lever pivots about a pin on which is keyed an L-shaped tumbler. The upper arm of the tumbler fits into a slot in the back of the striker within the breech block so that, when the under lever is lowered and the breech block pivots downwards, a cam between the two horns on the under lever rotates the tumbler backwards. This in turn pushes the striker backwards a short distance against the main spring which is then held in place when the nose of the trigger latches into a notch in the bottom arm of the tumbler.

As the under lever is closed and the breech block rises, the tumbler forces the striker further backwards against its main spring and fully cocks the trigger mechanism. There is an external tear shaped indicator arm on the right-hand side of the action body on the end of the tumbler pivot pin which tilts backwards to show the action is cocked. When the trigger is pressed, this releases the tumbler and striker, firing the round in the chamber. The breech block uses a knuckle joint at the back to transfer the firing forces directly to the action body rather than via the pivot pin.

The front of the receiver also includes an L-shaped extractor pivoted under the breech whose upper pair of fingers are pushed forward into slots either side of the chamber by the loaded cartridge rim. As the breech block opens, it pushes down on to the lower floor of the extractor rotating the extractor fingers backwards ejecting the cartridge.

A: Springs eased. B: Breech open. C: Action cocked and ready to fire

Henry Rifling

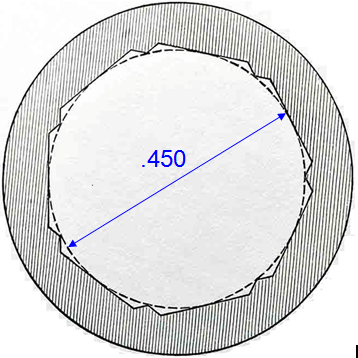

The Enfield Pattern 1853 rifle used what is now considered a conventional form of rifling consisting of sharp edged grooves and lands. However, in 1854 Sir Joseph Whitworth patented a new form of rifling that was polygonal in cross-section. In 1857, trials were carried out between the P1853 Enfield and a .451 calibre Whitworth rifle with hexagonal rifling. Although the Whitworth rifle proved vastly more accurate than the Enfield, it was rejected by the War Office because it was much more expensive to manufacture and was more prone to fouling.

Alexander Henry was a Scottish borne gun maker. In November 1860, he took out British Patent No. 2808 covering the design of a new form of rifling based on that of Whitworth but using flats with raised lands in between. In contrast with the need to use a mechanically fitted bullet in the Whitworth rifle, Henry relied on the use of a soft lead bullet that expanded into the rifling when fired. Although originally designed for muzzle loaders, the Henry rifling was successful when used in breech loaders in a slightly modified form. The advantages of the Henry rifling was that it was shallower than Whitworth rifling resulting in less fouling and the lands tended to grip the lead bullet better than other forms of rifling.

In the Martini-Henry rifle, seven flats were used with a right-hand twist of 1 turn in 22 inches. The nominal bore was .450 inch but was slightly enlarged at the breech tapering down to .450 inches after about 8 inches.

.577/.450 Boxer Cartridge

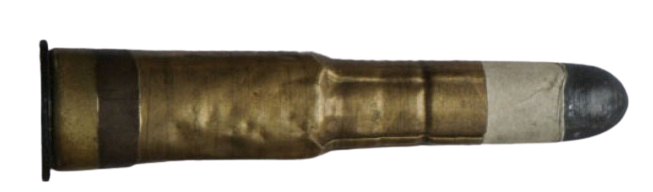

The .450 Boxer cartridge used in the original long chamber Martini-Henry rifle was straight sided and made from rolled brass foil and covered in brown paper. It used a separate double brass base cup with a steel base 0.030-0.035 inches thick containing a Boxer primer.

The main problem with the long cartridge was that it was susceptible to damage. Fortunately, before the design of the Martini-Henry rifle was finalised, a shorter bottle-necked cartridge was developed. The main part of the case was .577 inches in diameter with a .450 calibre bullet.

The new cartridge was referred to as the ‘Cartridge S.A. Ball Boxer Henry for 0.45 inch Martini Henry Rifle Short Chamber 85 Grain Mark I’ later shortened to ‘Cartridge S.A. Ball Rifle Breech-Loading Martini Henry Mark I’. The cartridge followed the previous Boxer design consisting of a case of .003 inch rolled brass sheet with a double brass base cup and steel bottom disk. The propellant was 85 gr of black powder with a bullet made from 12 parts lead to 1 part tin with a weight of 480 gr. The bullet was paper wrapped and lubricated in beeswax and there was also a thick beeswax wad underneath the bullet. The rolled brass Martini-Henry cartridge went through a number of small changes and, in Mk IV form, the propellant was reduced to 80 gr and the bullet to 410 gr to lesson the recoil of the weapon and make it similar to the Snider rifle.

The limitations of the rolled brass cartridge case were well known and, in 1885, a solid drawn brass cartridge was developed as the ‘Cartridge S.A. Ball Breech-Loading for Martini Henry Rifle .45 inch (Solid Drawn Case)’ later changed to ‘Cartridge S.A. Ball Martini Henry Rifle Solid Case Mark I’.

In 1885, the ‘Cartridge S.A. Ball Martini Henry Solid Case Mk II’ was introduced to overcome the problems with the Mk I. This continued in production until superceded by the ‘Cartridge S.A. Ball Martini Henry Solid Case Cordite Mk I’ in 1902. This round used 35.8 gr of Cordite with a 480 gr bullet.

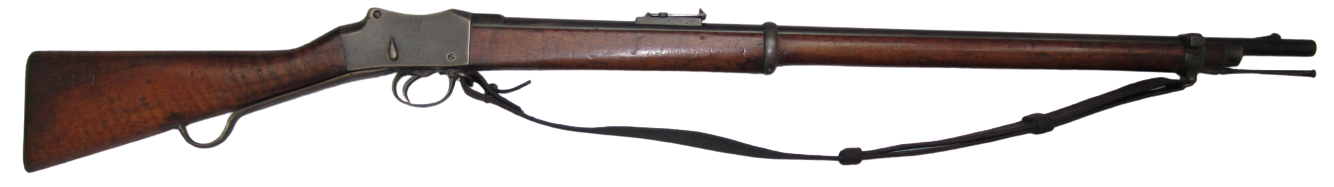

Martini-Henry rifle Mk I

The Martini-Henry Rifle Mk I was 49.25 inches long and weighed 8 lb 9 oz without the bayonet fitted with a barrel length of 33.2 inches. A barleycorn front sight was fitted mounted on a rectangular post. The rear leaf sight bed was marked from 100 to 400 yds in 100 yd steps; the ladder was marked from 500 to 1200 yds. A wide V-notch was provided for sighting up to 400 yds.

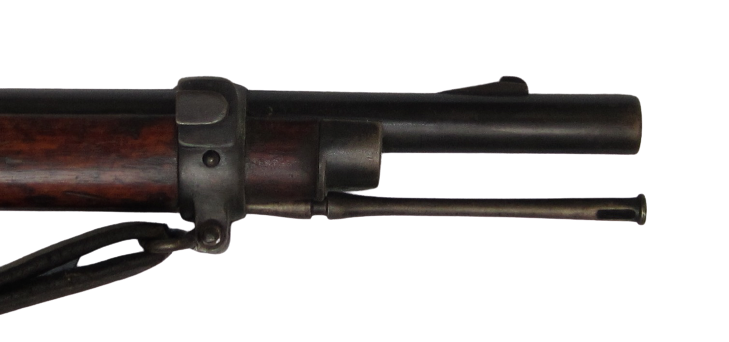

The fore-end stock extended to within 3 inches of the end of the barrel and incorporated a steel end cap. This cap had a slight lip at the back on the under side to slot into a groove in the cleaning rod to hold it in position. The fore-end stock was secured to the barrel by a front band with cross pin together with a mid band that was retained in place against a shoulder in the stock by a cross pin just in front of it. The front band incorporated an upper swivel for the leather sling along with a lug for a sword bayonet on the right-hand side. The lower swivel for the sling was attached to the front of the trigger guard. The rear of the fore-end stock was attached to the barrel via a cross pin through a bracket under the barrel about 1 inch from the receiver.

The butt stock slotted into a rectangular socket at the back of the receiver and was held in place via a large bolt inserted through the back of the butt. A steel chequered butt plate was used held in place via two screws.

The Martini-Henry Mk I evolved over time and was classified into 3 separate patterns. The 1st Pattern included a safety catch, chequered butt plate, wide V-notch backsight and butt mounted rear swivel. It was dated 1871 or 1872. The 2nd Pattern dated 1872-1874 featured an improved trigger but was otherwise similar to the 1st Pattern. The 3rd Pattern was dated 1874-1876 and was essentially similar to the Mk II that succeeded it with no safety catch.

Martini-Henry rifle Mk II

The Mk II was approved in 1877 and was manufactured up to 1880. The main changes compared with the Mk I are the smooth butt plate, a narrow V-notch in the backsight and no butt swivel. As with the Mk I, the Mk II featured a large cocking indicator on the right-hand side of the receiver body.

Martini-Henry rifle Mk III

The Mk III was approved in 1879. The main changes compared with the Mk II are a slightly longer rear sight bed, a double hump knox form and the use a hook plate instead of the cross-pin to support the rear of the fore-end stock. This plate hooked on to the front of the receiver and was then screwed into the underside of the fore-end stock. The Mk III is also distinguished in having a much small cocking indicator than the previous marks.

Martini-Henry Cavalry Carbine

This was approved in 1877 and featured a 21.3 inch barrel and was the first version of the Martini-Henry to feature the hook plate. The main change apart from the barrel length to the standard rifle was the use of a shorter backsight bed. This was marked up to 300 yds with the leaf marked up to 1000 yds. No provision was made for mounting a bayonet.

Martini-Henry rifle Mk IV

In 1881, the War Office started trials of a new smaller bore .402 cartridge and, in 1882, started trials with a new, so-called, Enfield-Martini rifle using this round. This rifle used a long under lever to produce better extraction of the cartridges. However, with the impending adoption of .303 magazine rifle, the plans for this rifle were abandoned in 1887.

Since a large number of the Enfield-Martini rifles had been manufactured, it was decided to convert them back to .577/.450 calibre for use in militia and volunteer units. This resulted in the .450 Martini-Henry Mk IV. There were 3 patterns of the Mk IV. The A Pattern was a conversion of the .402 trials rifles and have a short knox form and are dated 1887. The B Pattern was also a conversion but with a longer knox form and the foresight is mounted on a block with a trailing ramp. The C Pattern was newly made rather than being a conversion. One way of telling if the action body was converted was whether the IV mark on the right-hand side of the receiver body is central under the lock viewer’s mark. If converted from a Mk I Enfield-Martini, the ‘V’ was added later and therefore the ‘IV’ mark is not centred.

Martini-Henry Artillery Carbine

The Mk I artillery carbine was approved in 1879. It differed from the cavalry carbine in having provision for mounting the Pattern 1879 saw back sword bayonet with a lug provided on the right-hand side of the front swivel. It was also proved with a lower butt mounted swivel.

Later conversions of standard rifles to artillery carbines in the 1890’s led to the Mk II and Mk III. The Mk II had a cut down rifle barrel whereas the Mk III had a lighter carbine barrel.

.303 Martini-Henry Rifles and Carbines

After the introduction of the Lee-Metford rifle in 1888, some Martini-Henry rifles and carbines were re-barreled for the .303 round along with some newly made versions. These were referred to as Martini-Metford weapons. Following the introduction of smokeless propellants and the adoption of Enfield rifling, further conversions of Martini-Henry rifles and carbines were made to fire the .303 smokeless cartridge. These are referred to as being Martini-Enfield weapons.

Bayonets

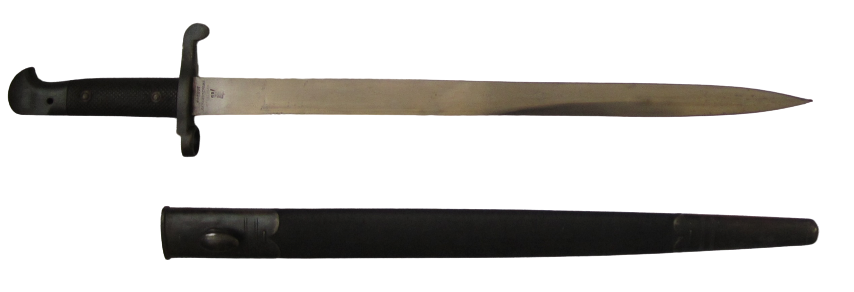

The Martini-Henry rifle was originally equipped with a version of the Pattern 1853 socket bayonet as fitted to the Enfield Pattern 1853 rifle. However, since the Martini-Henry barrel was of a smaller diameter, the bayonet socket had to be bushed to fit. The bushed bayonet was referred to as the Pattern 1853/72 socket bayonet and had a 17 inch triangular blade.

However, as the Enfield rifle was 6 inches longer than the Martini-Henry rifle, it was probably felt that, mounted on the latter, it was too short. Therefore, it was eventually replaced by the Pattern 1876 socket bayonet with a 22 inch blade. This was officially called the ‘Bayonet Common Long’. The bayonet fitted over the end of the muzzle and was then locked to the front sight post by rotating a locking ring. The early pattern had three brass rivets along the leather scabbard but this was changed to two in 1877. The scabbard had brass fittings and had an internal steel spring along its full length to provide rigidity and to hold the bayonet in place.

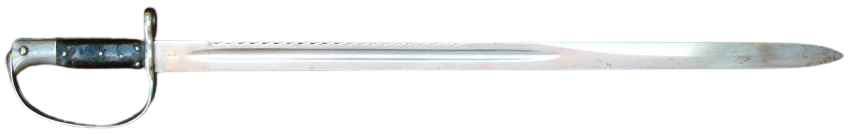

In 1886, it was decided to fit the new .402 Enfield-Martini rifle with a sword bayonet as it was felt that the Pattern 1876 had a tendency to bend or twist. The Pattern 1886 sword bayonet was the result. The first model was designed to to fit beneath the barrel but, in the second model, this fitted on the right of the barrel using the lug on the front barrel band. When the Enfield-Martini rifle was abandoned in 1887 to be converted into the Martini-Henry Mk IV rifle, the Enfield-Martini bayonets were modified slightly for the Martini-Henry Mk IV to become the Pattern 1887 sword bayonet. The Mk I had a fullered blade and flat latch spring. The Mk II used a coil spring with a fullered blade. The Mk II dispensed with the fullers and was slightly heavier.

The Pattern 1887 artillery saw back bayonet was originally based in the Pattern 1859 naval cutlass bayonet. The Mk I bayonet was manufactured to fit on the Mk I Martini-Henry artillery carbine. However, since the Mk II artillery carbine was a conversion from a standard Martini-Henry rifle with cut down barrel, a Mk II saw back bayonet was needed with bigger muzzle ring to over the large diameter of eh cut down barrel.

My Martini-Henry Rifles

I have three Martini-Henry rifles: a Mk II, a Mk III and a Mk IV. All three Martini-Henry rifles are fitted with original black buff leather slings.

My Mk II is dated 1888 and was made by BSA & M.Co. It is in very good condition and is equipped with a Pattern 1876 socket bayonet also in very good condition.

My Mk III is dated 1882 and made at Enfield. Again, it is in very good condition as is the Pattern 1876 socket bayonet fitted to it.

My Mk IV is dated 1886 and was made at Enfield. It looks as though it was a B Pattern conversion from a .402 Enfield-Martini rifle. It is fitted with a Pattern 1897 sword bayonet.

Martini-Henry Specifications

- Weight: 8 lb 9 oz

- Weight of Bayonet: 15 oz

- Length of Rifle: 4 ft 1.25 in

- Length with Bayonet: 5 ft 11 in

- Length of Barrel: 33.2 in

- Calibre: .450 in

- Cartridge: .577/.450 bottle necked rolled brass and solid brass

- Bullet: 480 gr lead

- Muzzle Velocity: 1200 fps

- Front Sight: Barleycorn

- Rear Sight Bed: To 400 yds

- Rear Sight Leaf: To to 1300 yds

- Rifling: Henry polygonal with 7 flats and lands

- Rifling Twist: Right-handed with 1 turn in 22 in

![]()