The British Army went to war in the Crimea in 1854 armed with the .702 Pattern 1851 Minié rifle-musket although one Division (the 4th) was still armed with the .750 Pattern 1842 percussion musket. Rather than being referred to as a rifle, the new arm was called a rifled musket on the orders of the Duke of Wellington to make clear the distinction between the infantry and rifle regiments. However, the Minié rifle-musket had some serious shortcomings. In addition to being prone to serious fouling of the bore, it also suffered from the weight of its ammunition which made it difficult for the average infantryman to carry the customary full load of 60 rounds.

Development of a replacement rifle was hindered by the Duke of Wellington’s insistence on the use of a large bore by the army. However, several months before Wellington’s death in September 1852, Lord Hardinge, Master-General of Ordnance, invited the principle gun makers in England to submit patterns for a smaller bore rifle for testing at the Royal Small Arms Factory (RSAF) Enfield. He also invited them to provide suggestions for improving the Minié bullet.

Six gun makers sent rifles for tests at Enfield that included Purdy, Richards, Lancaster, Wilkinson, greener and Lovell. Lovell was the inspector of small arms at Enfield at the time and he submitted a rifle in .577 calibre. As a result of these trials, two prototypes for the new rifle were produced at Enfield and, following further refinements, the design was adopted as the Enfield Pattern 1953 rifle-musket in .577 calibre.

Enfield Pattern 1853 rifle-musket

The Enfield rifle-musket used a barrel length of 39 inches. It was bored with three grooves with a right-hand twist of 1 turn in 78 inches (1:78). The barrel was attached to the one-piece stock via three barrel bands with the top one incorporating the upper sling swivel. The lower sling swivel was attached to the front of the trigger guard. The barrel was also attached at the rear via a bracket using a long screw through the stock into the front part of the brass trigger guard baseplate. This baseplate extended 3 inches behind the trigger guard and was fixed to the stock via two wood screws.

The trigger lock mechanism was held in place by two horizontal screws whose heads protrude from the brass ferrules on the left-hand side of the stock. In the lock, the trigger was connected internally to a tumbler on which there was both half-cock and full cock notches. These notches were engaged by the sear when the hammer was cocked backwards. The horizontal bar on the sear that engages with the trigger mechanism can be seen bottom right below along with the sear spring just above it. The trigger forces the sear bar upwards to release the hammer. The hammer main spring can be seen occupying the front of the lock mechanism.

The trigger lock mechanism was held in place by two horizontal screws whose heads protrude from the brass ferrules on the left-hand side of the stock. In the lock, the trigger was connected internally to a tumbler on which there was both half-cock and full cock notches. These notches were engaged by the sear when the hammer was cocked backwards. The horizontal bar on the sear that engages with the trigger mechanism can be seen bottom right below along with the sear spring just above it. The trigger forces the sear bar upwards to release the hammer. The hammer main spring can be seen occupying the front of the lock mechanism.

The Enfield rifle-musket was fitted with a barleycorn front sight mounted on a rectangular block. The rear sight consisted of a leaf graduated up to 400 yds in 100 yd steps on the bed, with the ladder graduated up to 800 yds. The rifle-musket was fitted with the Pattern 1853 socket bayonet with a 17 inch triangular blade and came with a leather scabbard with brass fittings.

The one piece stock extended to within 3 inches of the end of the barrel and was fitted with a brass end cap. The rifle-musket came with a ramrod that fitted into a groove in the underside of the fore-end stock and was retained by the barrel bands. The butt stock was fitted with a smooth iron butt plate held in the stock by two wood screws.

Pattern 1853 Enfield Minié Bullet

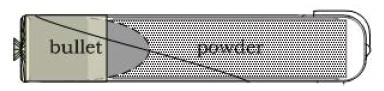

In parallel with the development of the new rifle, modifications were also considered to the Minié bullet used in the Pattern 1851 Minié rifle-Musket. This fired a .690 calibre bullet that used a similar conical lead bullet to that invented by Captain Claude Etienne Minié in 1849 with a hollow in the base incorporating an iron cup to aid the expansion of the bullet into the rifling. The original Minié bullet used 4 tallow grease filled grooves or cannelures to aid loading of the bullet and to reduce fouling of the bore. However, in the Pattern 1851 Minié rifle-musket, the grooves were omitted and the bullet was smooth sided.

The Pritchett Bullet

The competition for the Minié bullet for the Pattern 1853 Enfield rifle-musket was won by Robert Taylor Pritchett who was a 23 year old gun maker working for his father’s firm. Pritchett was acquainted with William Ellis Metford ( of Lee-Metford rifle fame) who may have been first to suggest the use of a hollow-based bullet for the Enfield rifle that expanded without a plug. However, Pritchett was eventually credited with the design of the first Pattern 1853 Enfield bullet. The Pritchett bullet was of solid lead with .568 calibre and weighed 529 gr using a propellant of 68 gr of black powder. The .577 bore in the barrel was rifled with 3 rectangular grooves with a right-hand twist of 1 turn in 78 inches.

The Hay Bullet

However, due to manufacturing tolerances in these bullets and the manufacturing tolerances and wear in the rifle bores, it was found that the Pritchett bullets did not always expand properly into the rifling resulting in accuracy problems. To overcome this, the bullet was modified and an iron cup re-introduced using a larger cavity in the base of the bullet. This was recommended by Lt Colonel Charles Crawford Hay who was the Superintendent of the School of Musketry. The result was known as the Hay bullet. The design was subsequently modified to use a Boxwood plug which was found to give better expansion of the bullet, less fouling and increased shooting accuracy.

The Boxer Bullet

Captain Edward Mounier Boxer was the Superintendent at the Royal Laboratory at the Royal Arsenal in Woolwich. He was responsible for introducing an improved lubricant in 1957 composed of 5 parts beeswax to 1 part tallow since it had been proved that the use of tallow on its own resulted in oxidation of the lead bullets. Captain Boxer also recommended the reduction in the diameter of the bullet to .550 inches to provide easier loading. The Boxer bullet proved a success without any reduction in performance.

The Paper Cartridge

The cartridge was constructed using two weights of paper. The inner tube was made of heavy cartridge paper and held the gunpowder while the outer covering was of lightweight paper. The bullet was placed at the bottom of the cartridge. It was lubricated not only to make loading easier but was also used as an anti-fouling agent to help clean the bore of powder residue. It was wrapped in a lubricated paper patch which had three slits cut in it to allow lubricant through and to aid the paper breaking apart on leaving the muzzle.

To load a cartridge, the end of the paper tube was torn off, either using the fingers or teeth, and then the powder contents poured down the barrel. The cartridge was then turned over and the bottom of the bullet lodged into the muzzle. The excess paper was then torn off before the bullet was rammed down the barrel.

Pattern 1856 Two-Band Enfield Rifle

A shortened version of the Pattern 1853 rifle-musket was produced in 1856 with the barrel reduced by 6 inches to 33 inches in length. This used the same rifling as the rifle-musket and was intended for use by sergeants in infantry regiments and by the rifle regiments to replace the Baker and Brunswick rifles used previously. It is generally referred to as the 2-band Pattern 1856 Enfield rifle.

The 2-band Enfield rifle was normally fitted with the Pattern 1853 socket bayonet but the barrel was also equipped with a lug on the right-hand side to take the Pattern 1856 Yataghan sword bayonet.

Pattern 1856 Enfield Cavalry Carbine

Pattern 1856 Enfield Cavalry Carbine

This was adopted by the cavalry and had a 21 inch barrel and used the same 3-groove 1:78 rifling of the P53 rifle-musket. It was equipped with a flip up rear sight for either 200 yds or 300 yds.

Pattern 1858 Naval Two-Band Enfield Rifle

The Pattern 1858 Naval Two-Band Enfield rifle was similar to the Pattern 1856 army rifle but used brass rather than steel furniture. The rifling of the barrel was also different in using 5 grooves and a right-hand twist of 1 turn in 48 inches (1:48). The backsight leaf was graduated to 1100 yds.

Pattern 1860 Two-Band Enfield Rifle

This was the army’s version of the Naval Pattern 1858 rifle and used the same 5-groove rifling. As with other army rifles, it used steel rather than brass furniture.

Pattern 1861 Two-Band Artillery Rifle

The Pattern 1861 Two-Band carbine employed a 24 inch barrel and was used for personal protection for artillery units. It was fitted with a fixed rear sight and was probably accurate up to 500 yds.

My Pattern 1853 Enfield Rifle-Musket

My Pattern 1853 Enfield rifle-musket is in very good condition. It is dated 1858 and marked ‘Tower’. It is fitted with a Pattern 1853 socket bayonet with a scabbard that is in very good condition with no damage visible.

Enfield Rifle-Musket Specifications

- Weight: 9 lb 7 oz

- Weight of Bayonet: 11 oz

- Length of Rifle: 4 ft 7 in

- Length with Bayonet: 5 ft 11 in

- Length of Barrel: 39 in

- Calibre: .577 in

- Cartridge: Paper containing propellant and Minié bullet

- Bullet: 530 gr lead

- Muzzle Velocity: 900 fps

- Front Sight: Barleycorn

- Rear Sight Bed: To 400 yds in 100 yd steps

- Rear Sight Leaf: To 800 yds or 1250 yds depending on model

- Rifling: Three grooves

- Rifling Twist: Right-handed with 1 turn in 78 in

![]()