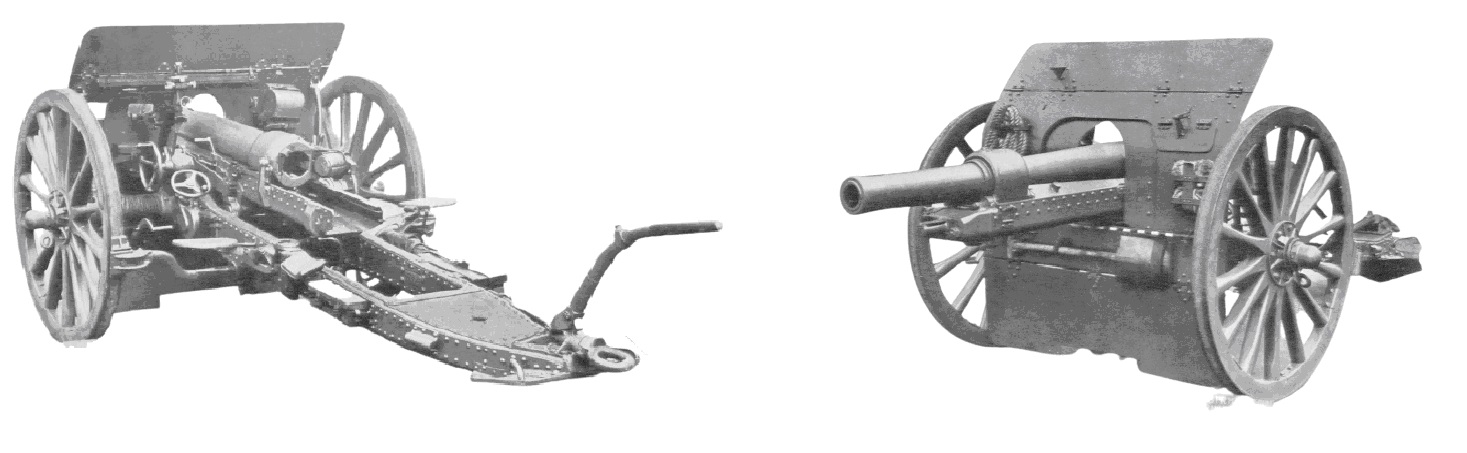

During the 2nd Boer War (1899-1902), the main field gun in use by the British Army was the breech-loading 15-Pdr BL Gun that was introduced into service in 1892. It used the smokeless propellant Cordite and fired shrapnel shells to a maximum range of 6,000 yd. Although it was equipped with elementary devices to limit the recoil of the gun, it still needed to be re-laid before firing the next shell.

However, in 1897, the French adopted the famous Matériel de 75 mm Mle 1897 or French 75 that incorporated the first effective hydro-pneumatic recoil system for a field gun. This system completely absorbed the recoil of firing and automatically returned the barrel ready for the next round allowing a maximum of at least 20 rounds a minute to be fired out to a range of 9,300 yds. The introduction of the French 75 more or less rendered every other field gun obsolete. In British terminology at that time, this type of gun was referred to as quick-firing (QF). This was not only because of the recoil system but also because brass cartridges were used that provided the necessary obturation (sealing of the breech) and removed the need to swab out the breech each time a round was fired.

In 1901, the Special Committee on Horse and Field Artillery Equipment was established with Cabinet approval chaired by Major-General George Marshall who was a former artillery commander in South Africa. He brought together other artillery commanders with war experience to establish the requirements for quick-firing field guns covering both a horse artillery gun and a field artillery gun. Of the entries received, 5 were selected for the horse artillery and 3 for the field artillery and their makers were then invited to submit prototypes.

These were tested in 1902 but none was found to satisfactory. The makers were therefore called to a conference and agreed to collaborate on a composite design that eventually resulted in using the Armstrong gun, the Vicker’s recoil system and the Royal Ordnance Factory Woolwich sighting and elevating gear and ammunition carrying. Trials of the composite guns took place in 1903 and the guns were accepted into service in 1904. The Royal Field Artillery were provided with the 3.3 inch calibre 18-Pdr QF Gun while the Royal Horse Artillery were provided with a 3 inch calibre 13-Pdr QF Gun but with the barrel shortened by 2 feet and the weight reduced by 589 pounds.

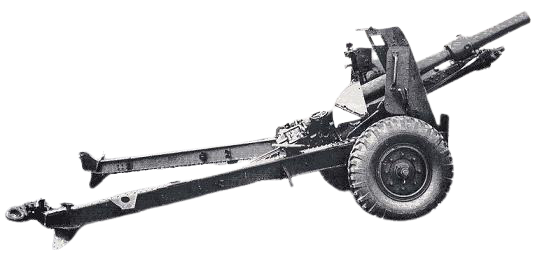

The 18-pdr went through Mks I-V ending up in Mk V form with a split trail and with a hydro-pneumatic recoil system mounted under the barrel. In Mk IV form, many were relined to increase the bore from 84 mm to 87.6 mm to fire a 25-pdr shell in which form they were designated the QF 18/25-Pdr Mk I many of which were lost during the Dunkirk evacuation. These were eventually replaced by the QF 25-Pdr Mk II on its own specially designed carriage.

Gun Design

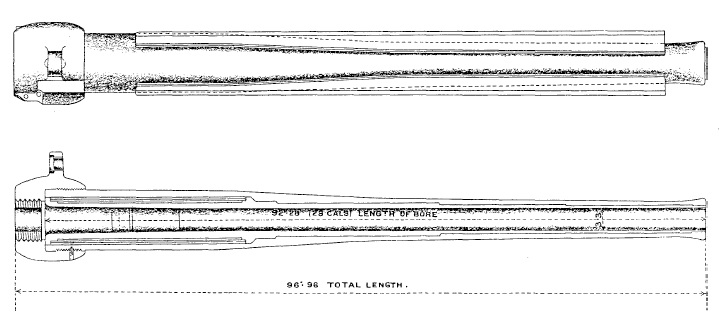

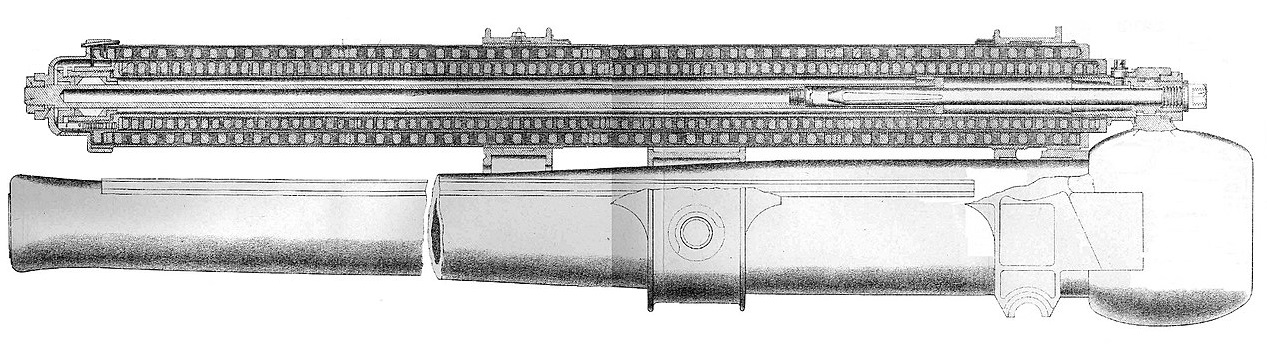

The Mk I gun barrel was made up of a rifled A-tube extending from the rear end of the chamber to the muzzle. Over the rear portion of the A-tube was wound successive layers of steel wire and then a jacket was shrunk over the wire and the A-tube. The jacket was fitted with longitudinal projections on each side to form guides as it recoiled within the gun cradle. The breech ring was screwed into the end of the jacket.

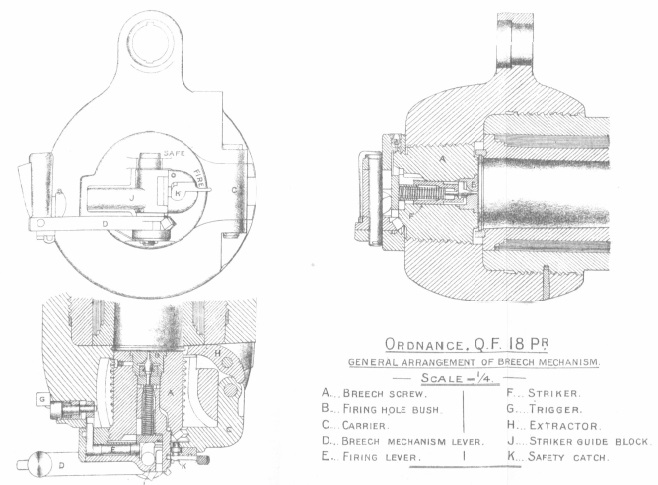

The gun fired fixed rounds with brass cartridges and was fitted with a ‘Single Motion Breech Mechanism’. This required one pull of the operating lever to unlocked the interrupted thread breech and to swing this out of the way to enable a new round to be loaded. After loading, one push of the lever then closed the breech and locked it into position. The breech was fitted with an extractor that automatically operated when the breech was opened and ejected any spent cartridge.

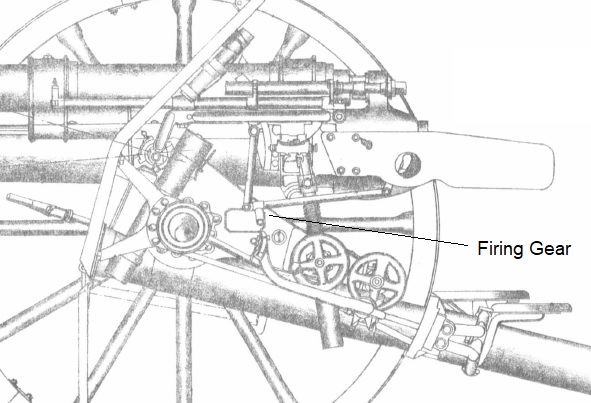

The gun was fired using the firing lever on the left-hand side of the breech – when rotated backwards by either the firing gear on the left side of the cradle or by an attached lanyard, this initially pulled the striker within the breech backwards against its spring and then released it to strike the primer in the loaded cartridge. The firing gear consisted of a firing handle fitted on the front of a control lever attached to front and rear arms that each pivoted on the cradle as shown. The rear arm pivoted against the firing lever when the firing handle was pulled backwards firing the gun.

Carriage Design

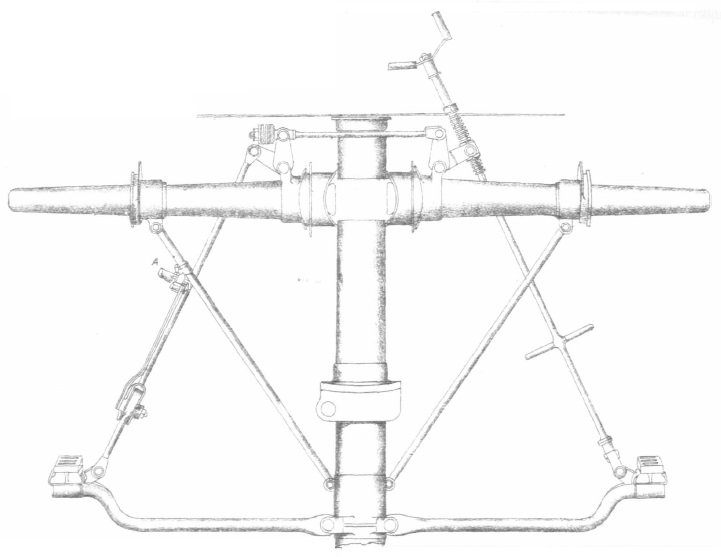

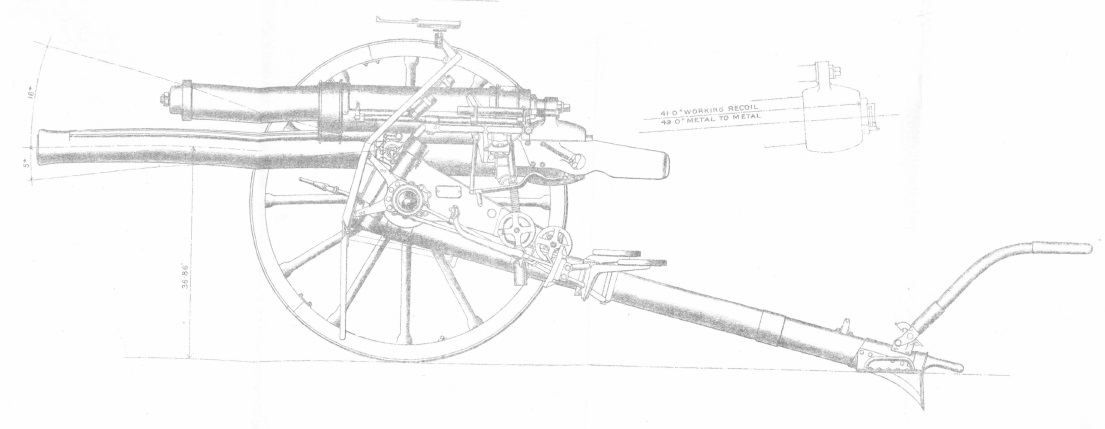

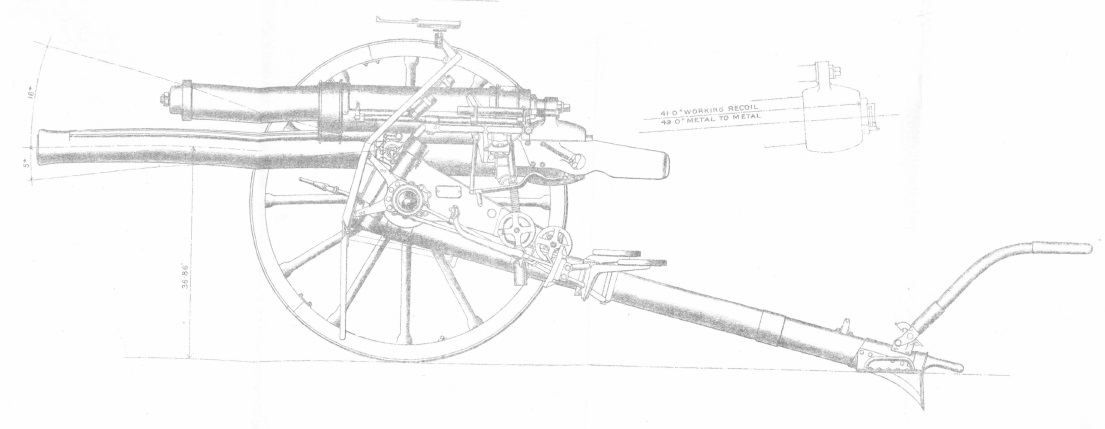

The carriage was fitted with a tubular steel trail with a spade and traversing lever on the end. The trail was attached to the axletree via a bracket that also served as the pivot for the carriage body (saddle). The axletree was fitted with 5 foot wooden wheels with 3-inch steel tyres. The gun shield was attached to the axle tree. Leather cases were provided on the shield for the dial sight, field clinometer, sight clinometer, spare parts, fuze keys, shovel, aiming posts, breech and muzzle covers, oil can, fuze indicator, tool case and telescope. The carriage was fitted with brake shoes on the ends of arms that pivoted off the side of the trail to act against the rear of the wheels. They were operated by a brake handle at the front of the carriage.

The carriage body consisted of two triangular shaped frames connected by transoms and was fitted with a bearing to allow it to pivot on the axletree during traversing . The cradle was made of bronze with trunnion arms to allow it to pivot in elevation in bearings on the carriage body. It had an opening and guides in the lower part along which the gun recoiled. In the upper part it had an opening for the spring case that was fixed to it.

The rear of the carriage body was attached to a screw jacket fixed to the trail that allowed the gun to be traversed by up to 4.5° to either the left or right. Traversing was achieved using the traversing hand wheel on the left of the carriage. The rear of the carriage body was also equipped with a clamp activated by a lever and used when travelling.

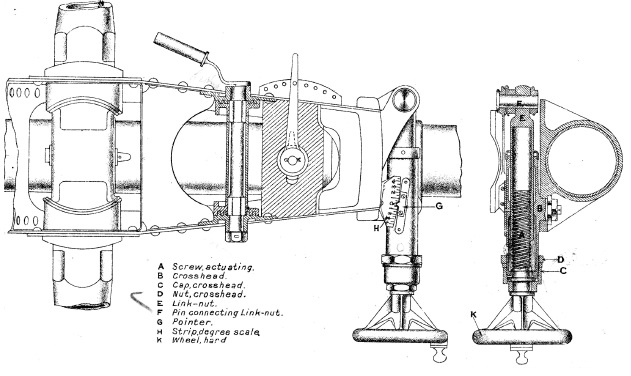

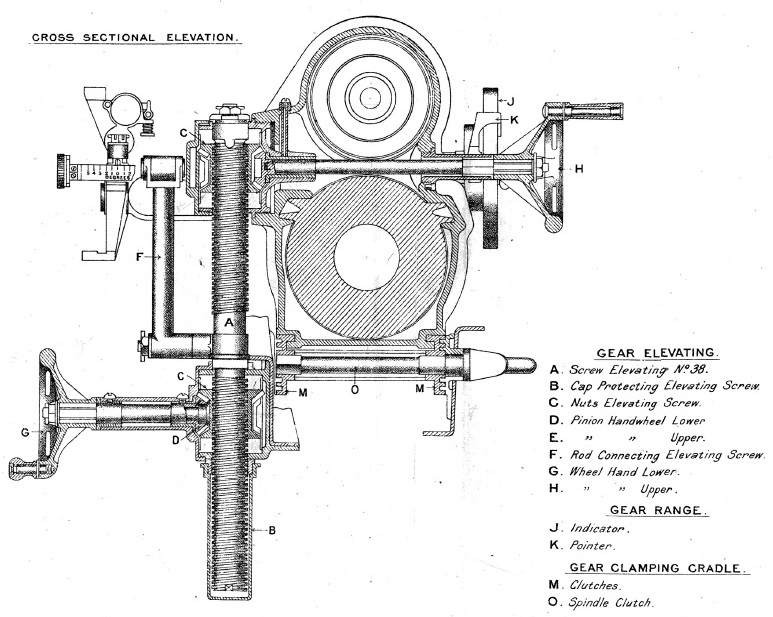

The gun was elevated via an elevating screw on the left-hand side of the cradle that was double ended. The gun layer’s hand wheel raised or lowered the elevating screw and in so doing raised or lowered both the sight bracket and the gun and cradle. This hand wheel allowed the angle-of-sight (AS) to be set on the gun. The hand wheel on the right-hand side left the sight bracket unaltered but independently raised or lowered the gun and cradle – this therefore applied tangent elevation (TE) to the gun. The right hand wheel was provided with a range drum that was graduated on its face to 6,200 yd by means of a pointer in 50 yd intervals. The periphery of the drum was graduated to 16 degrees in 10 minute intervals. In practice, the sum of the AS and TE was the quadrant elevation (QE) for the gun.

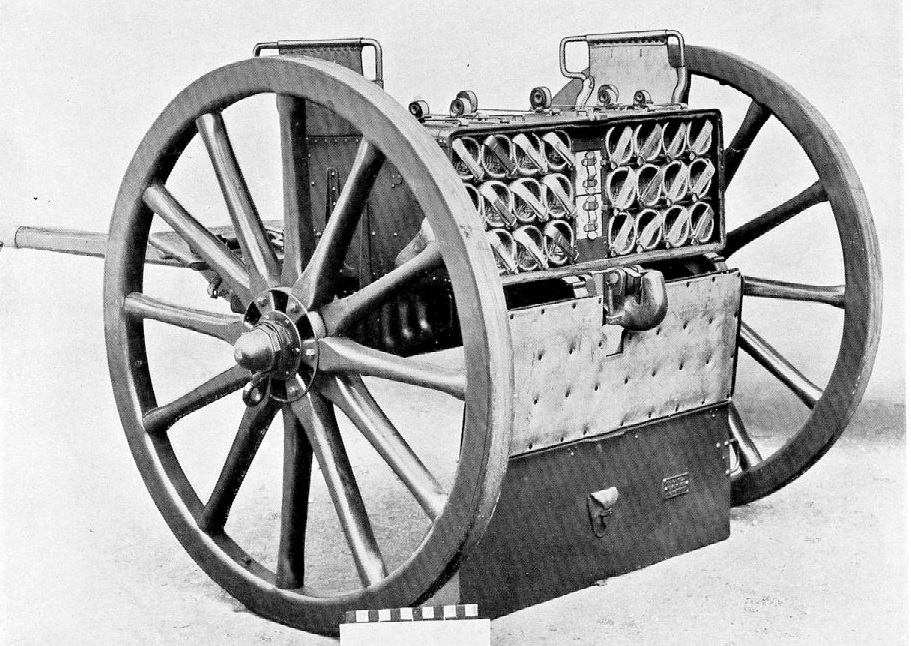

Limbers

The new guns were fitted with standard 5 foot wooden wheels and were towed behind a limber that was pulled by 6 horses. The carriage limber carried 24 rounds of ammunition and other stores and was normally deployed in the field to the left of the gun with its cover and shield plate folded down to provide protection the detachment members. The ammunition wagon was towed behind its own limber pulled by 6 horses. The ammunition box on the ammunition limber and wagon both held 38 rounds. In total, the carriage limber and ammunition limber and wagon carried 108 rounds.

Recoil System

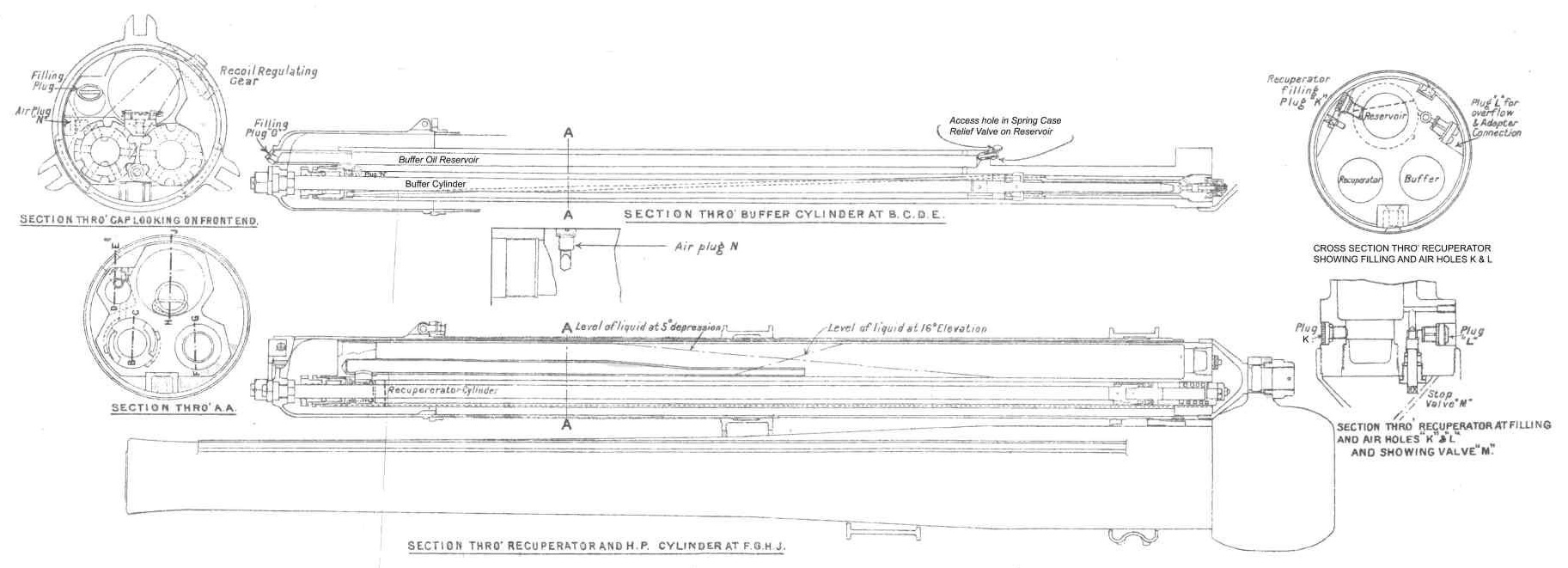

The 18-pdr employed a hydro-spring recoil system. In contrast with most field guns at the time and since, the new British field guns mounted the recoil mechanism above the gun barrel. The recoil mechanism was contained within the outer spring case that was fixed to the cradle. Within the outer case was an outer spring supported on the outside of the inner spring case. Inside the inner spring case was the inner spring and within that the hydraulic buffer.

The hydraulic buffer consisted of a cylinder that was attached at the rear to a lug on top of the breech ring. The buffer contained a piston on the end of a rod that was bolted to the front of the outer spring case. As the gun recoiled, the buffer cylinder was pulled backwards and oil had to flow past the piston from the front of the cylinder to the rear. The inner surface of the cylinder was grooved to allow the mineral oil to move rearwards past the piston creating the damping force required to absorb the recoil of the gun.

As the buffer cylinder recoiled backwards, a flange on the front of it pressed against the front end of the inner spring compressing it against the rear of the inner spring case. This in turn forced the inner spring case to move backwards and caused the flange on the front of it to press against the outer spring compressing it against the rear of the outer spring case. Thus, when the gun recoiled, the hydraulic cylinder and the inner spring case telescoped backwards out of the outer spring case. The maximum recoil of the gun was 41 inches.

When the recoil ended, the springs pushed the gun back into battery. However, towards the end of the forward movement, a control rod at the rear of the buffer cylinder entered the hollow piston rod that was filled with oil. Forcing the oil out through small holes dampened the final stages of movement and brought the run out to a smooth end.

Sighting Systems

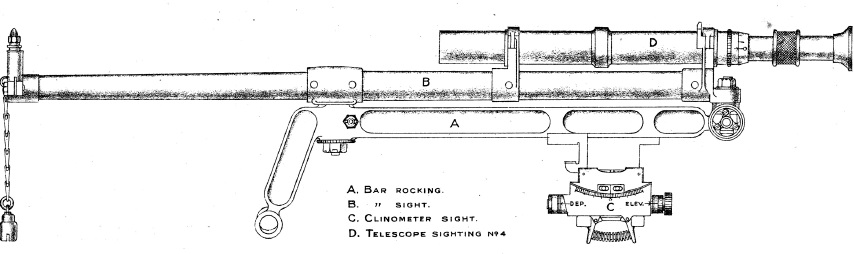

In previous times, tangent sights were mounted on the gun barrel and used to aim field guns. However, with quick-firing guns, this method of aiming was too slow and, therefore, the 18-Pdr QF Gun entered service with a rocking-bar sight that provided either open sights (front bead and rear notch) or a No. 4 telescopic sight. This type of sight provided an independent line of sight and allowed the gun layer to keep his sight on the target and was not affected by either the elevation or recoil of the gun.

The rocking-bar pivoted at the front via an extension of the left-hand gun trunnion and connected at the rear to a rod driven by the gun’s elevating gear. The gun detachment No. 3 or gun layer sat to the left of the gun barrel and was responsible for using the sights to aim to gun. To align the rocking-bar sights on the target, he used two hand wheels. The rear one was used to transverse the gun by up to 4.5 degrees to either side – this pivoted the complete gun carriage about a pivot on the axle tree. The other hand wheel that was referred to as the lower elevation wheel was used to elevate both the rear of the rocking-bar sight and the gun cradle. This hand wheel was used to align the sights on to the target and the elevation given to the gun at the same time was intended to compensate for the difference in height between the gun and the target. The elevation angle set up is called the ‘angle of sight’

The gun detachment No. 2 sat to the right of the gun and was responsible for opening and closing the breech and for setting the range for the gun. He did this by using the upper elevation wheel on the right-hand side that elevated the gun between +16 and -5 degrees . When operated, the upper elevation wheel did not move the rocking-bar sight maintaining an independent line of sight to the target. The No. 2 was provided with a range indicator dial that was graduated in both degrees and yards out to 6,200 yds. The additional elevation angle set up for the gun was called the ‘tangent elevation’.

The rocking-bar sight was used in direct fire mode when the target was visible to the gun layer. However, during the Boer War, both sides in the conflict made limited use of indirect fire although the means for doing this were very primitive at the time. Indirect fire requires both the elevation and azimuth of the gun to be set without being able to see the target by the gun crew.

Dial Sights

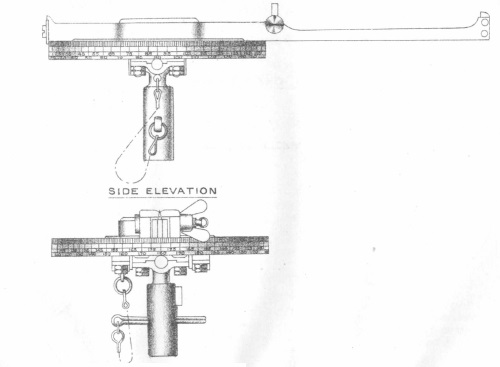

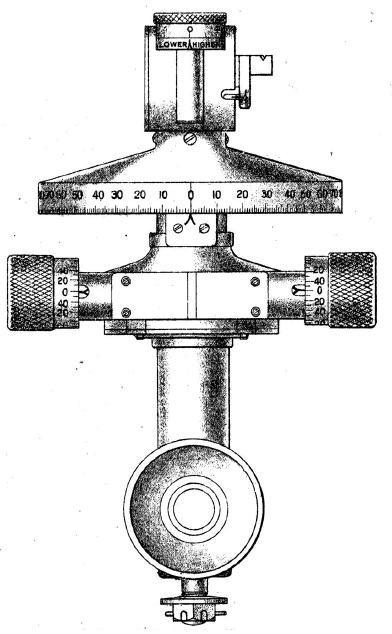

In the 18 Pdr, a clinometer was provided on the rocking-bar sights and used with the range dial to allow the elevation of the gun to be set in indirect fire mode. The problem of setting the azimuth direction for the gun in indirect fire mode was much more difficult. Originally a No. 1 dial sight was used mounted on the front of the shield as shown.

The No. 1 dial sight was provided with pivots to allow it to be levelled to compensate for the carriage wheels not being level. It was fitted with a turntable carrying an open set of sights with a bearing scale on the outside marked in degrees. In practice, the target direction was defined for the gun by an offset bearing relative to an aiming point that could be a natural future on the landscape or could be aiming posts specially set up some distance from the gun. To lay the gun for line, the offset target bearing was set up on the sight and then the gun traversed until the aiming point was aligned with the open sight.

The No. 1 dial sight was difficult to use except when the aiming point was in front of the gun. If the aiming point was behind the gun, the gun layer had to move round in front of the shield to use it which was not ideal. A much better solution came with the introduction of the No. 7 dial sight in 1910 that was based on the German Goertz periscopic panoramic sight. It was mounted on a bracket next to the rocking-bar sight.

The No. 7 dial sight consisted of a fixed eye piece at the bottom and a sighting head at the top that could be rotated in azimuth by 180 degrees in either direction. It was fitted with an azimuth dial and micrometers to allow the azimuth angle for the sighting head to be set very accurately. Indirect fire was achieved by pointing the gun in azimuth by a pre-determined number of degrees offset from a reference direction that could be seen in the dial sight. The reference direction could be towards a known feature in the landscape or it could be achieved by using sighting posts some distance away placed in the ground. The advantage of the No. 7 dial sight was that the gun aimer could remain in his seat to look through the sight and then view the reference target in any azimuth direction but usually behind the gun.

a sighting head at the top that could be rotated in azimuth by 180 degrees in either direction. It was fitted with an azimuth dial and micrometers to allow the azimuth angle for the sighting head to be set very accurately. Indirect fire was achieved by pointing the gun in azimuth by a pre-determined number of degrees offset from a reference direction that could be seen in the dial sight. The reference direction could be towards a known feature in the landscape or it could be achieved by using sighting posts some distance away placed in the ground. The advantage of the No. 7 dial sight was that the gun aimer could remain in his seat to look through the sight and then view the reference target in any azimuth direction but usually behind the gun.

One of the issues in aiming all rifled weapons is accounting for the spin drift of the projectiles. This is caused when the spin axis of the projectile starts to deviate from the direction of travel as the range increases. This, in turn, results in the drag force on the projectile producing a gyroscopic force that will move it in azimuth to the right when the spin is clockwise and to the left when the spin is counter-clockwise creating a drift in that direction. The Ordnance 18 Pdr QF Gun imparted a right-hand spin to each shell causing a spin drift to the right. This was compensated for in the gun by tilting the axis of the trunnions down on the left-hand side by 1.5 degrees that then resulted in the muzzle moving to the left as the gun is elevated.

Gun Detachment Roles

The gun detachment consisted of 10 men of whom 6 worked at the battery and the remaining 3 formed a reserve. The duties of the detachment during WW1 were:

No. 1: Commanded the gun detachment positioned at the rear of the trail, responsible for re-positioning the spade on the end of the trail when more than 4.5 of traverse was needed.

No. 2: Sat to the right of the gun barrel and was responsible for opening and closing the breech and for setting the gun’s elevation and therefore its range – he was termed the ‘Range Setter’.

No. 3: Sat to the left of the gun barrel and was responsible for aiming the weapon and for firing it – he was termed the ‘Layer’.

No. 4: Stood to the left of the trail and was responsible for loading the next round into the breech – he was termed the ‘Loader’.

No. 5: Stood near the limber and was responsible for checking the fuzes and for handing the rounds to the No. 4 – he was termed a ‘Fuze Setter’.

No. 6: Stood near the limber and was responsible for extracting the next round from the limber and for setting the fuzes – he was termed a ‘Fuze Setter’.

No. 10 was the next senior NCO who was stationed at the ammunition wagon line along with Nos. 7, 8 & 9 who replaced any casualties at the battery.

However, later in WW1 when static artillery became the norm, it was usual for the use of the limber to be dispensed with in action and shells were stacked on the ground close to the gun requiring a smaller detachment to operate the weapon.

When travelling, the No. 1 & 10 rode on horses stationed to the left of the front horse in the carriage and ammunition wagon limber, respectively. The Nos. 2, 3 & 4 rode on the left-hand carriage limber horses, the Nos. 5, 6 & 7 rode on the left-hand ammunition wagon limber horses and the Nos. 7, 8 & 9 sat on the ammunition wagon limber.

18-Pdr Gun Mk II

The original Mk I gun barrel was changed during WW1 to allow a worn out A-tube to be replaced more easily. The Mk I A-tube was inserted into the gun jacket after the latter had been heated up to expand it. In the Mk II gun, both the A-tube and the jacket were slightly coned to allow hydraulic pressure to be used to insert the new A-tube. Both marks of gun used wire wrapping over the rear third of the A-tube for strengthening purposes. All Mk I guns with an A-tube replaced in this way were designated Mk I*.

18-Pdr Mk I Carriage

As WW1 settled into trench warfare, it was found that after prolonged firing, the running out springs could fail, sometimes exacerbated by damping oil loss that was also used as a lubricant. In order to improve the situation, an armoured oil reservoir was added to the Mk I carriage at the front of the spring case.

18-Pdr Mk II Carriage

To fully overcome the problem with the recuperator springs, the Mk I carriage was updated in 1916 as the Mk II carriage with a change to a hydro-pneumatic recoil system together with a lengthened cradle to give greater stability to the gun when recoiling. In the Mk II, the existing spring case was extended in length with the addition of a 10 inch long bolt-on malleable brass end piece to accommodate the new recoil system. Existing Mk I carriages were modified and designated as the Mk I*.

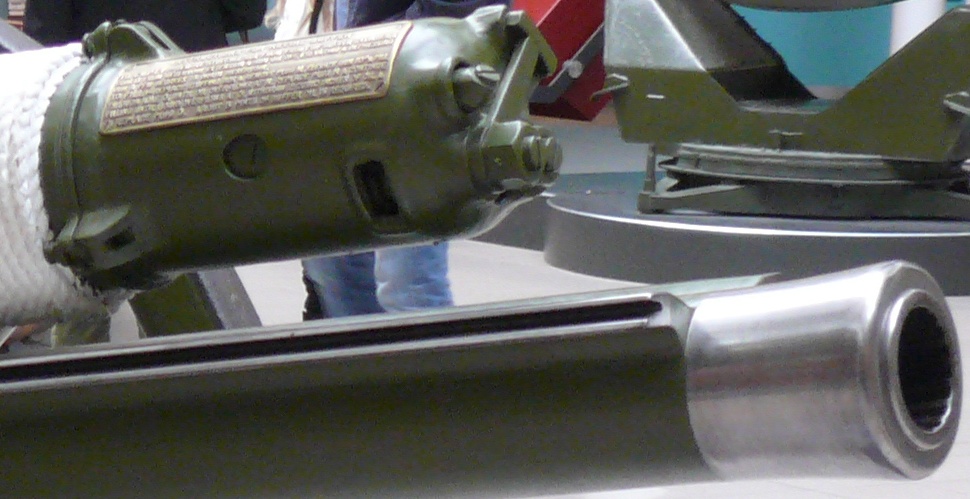

The new recoil system consisted of a cylinder block within the lengthened spring case that was bolted to the breech lug at the rear. The cylinder block was also attached to the gun via a hoop near the front. Four cylinders were bored in the cylinder block. In the lower part on the right was the buffer cylinder and on the lower left was the recuperator cylinder. In the centre above these two cylinders was the high pressure air cylinder and to its right was an oil reservoir for the hydraulic buffer.

The hydraulic buffer was filled with oil and contained a piston at the rear on the end of a rod that was bolted to the front cap on the spring case. The piston was made up a front part fixed to the piston rod containing two ports to allow for the passage of oil during recoil. Behind the fixed piston was a recoil valve which was free to rotate on the piston rod but was fitted with a pair of keys that engaged in spiral gloves cut into the inside of the buffer cylinder. The recoil valve was also fitted with two ports. At the start of the recoil, the ports in the piston and recoil valve were approximately aligned allowing a restricted flow of oil which adsorbed some of the gun’s recoil energy. However, as the gun recoiled, the recoil valve rotated because of the spiral grooves which gradually closed off the flow of oil bringing the recoil to an end. The length of recoil could be adjusted by moving the arm connected to the piston rod on the front of spring case front cap with the working recoil length being 45 inches The filler plug for topping up the oil reservoir was accessible via the front cap.

The recuperator cylinder contained a piston at the rear on the end of a rod that was also bolted to the spring case front end cap. As the gun recoiled, the oil in front of the piston was forced through an open retarding valve into the air cylinder where the air was compressed helping to absorb the recoil energy. When the recoil came to an end, the resulting air pressure then forced oil through small holes in the now closed retarding valve back into the recuperator cylinder forcing the gun forward back into battery. In order to bring the gun to a gentle stop, the back end of the hydraulic buffer piston rod was formed into a pointed control rod which had to force out the oil in the control cylinder absorbing the remaining recoil energy. The air cylinder was pressurised to 600 psi initially to keep the gun fully run out.

18-Pdr Mk III Carriage

18-Pdr Mk III Carriage

The Mk III carriage was introduced into service in 1916. The main disadvantage with the original Mk I and Mk II carriages was the limited elevation range for the gun of +16 degrees produced by the use of a pole trail. In the Mk III carriage, the maximum elevation was increased to 30 degrees by using a box trail with space for the gun to recoil within its two arms. This increase in maximum elevation angle resulted in an increase in maximum range for the gun to 9,100 yd. In the Mk III* carriage, a modification to the elevating gear and the position of the trunnions then resulted in a maximum elevation angle of 37.5 degrees.

In the Mk III carriage, a new hydro-pneumatic recoil system was introduced that was mounted in the cradle below the gun. It was essentially of a similar design to that in the Mk II but with two noticeable changes. The first was the use of a floating piston in the air reservoir to separate the oil from the compressed air. This was fitted with an indicator rod at the front that could be observed though a slot in the cradle front cap to allow the oil level in the recuperator to be visually checked.

The other change compared with the Mk II was the fitting of a variable cut-off gear that reduced the length of recoil from 48 inches when the gun was horizontal to 26 inches with the gun at maximum elevation to prevent the breech hitting the ground during recoil. The cut-off gear consisted of control rod that pivoted on the carriage near the right-hand gun trunnion and was connected to an operating arm near the front of the cradle. When the gun was elevated, the control rod rotated the operating arm anti-clockwise which in turn rotated the buffer piston rod via a set of gears which reduced the distance necessary for the rotating valve to stop the flow of oil and to bring the recoil to an end.

In the case of the Mk III carriage the buffer oil reservoir was no longer inside the cylinder block but was fitted around the front gun mounting hoop and connected to the buffer cylinder towards the rear via a pipe.

The Mk IV gun was designed for use with the Mk III carriage with the Mk III gun being purely an experimental anti-aircraft gun. The Mk IV gun was similar to the Mk II in construction but featured a new breech mechanism with an operating lever of the right-hand side of the breech.

18-Pdr Mk IV Carriage

By 1919, the standard British Army field gun was the QF 18-Pdr Mk IV using a Mk IV gun. The main difference with the Mk III carriage was a new traversing mechanism to give a quicker and easier traverse.

QF 18-Pdr Mk V Carriage

The Mk V carriage was equipped with a split trail and entered service in 1923. It allowed 25 degrees left and right traverse without moving the trail and provided up to 37.5 degrees elevation. However, in the 1930’s, all the army’s artillery were converted to mechanised towing. Initially, the Mk IV and Mk V guns in service had solid rubber tyres added to the standard wooden wheels but the axles and wheels were eventually changed to steel wheels and pneumatic tyres. The converted carriages were designated the Mk IVP or Mk VP. From 1938, many of these guns were converted to 25-pdr by changing the barrel liners to ones with a bore from 84 mm to 87.6 mm.

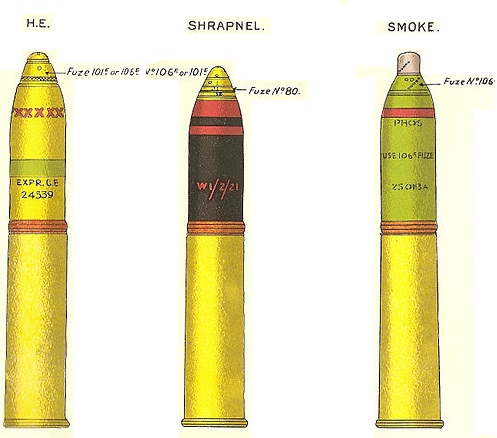

Ammunition

The QF 18-Pdr fired four types of fixed ammunition: high explosive (HE), shrapnel, smoke and gas. The HE Shell was filled with Lyddite, TNT or Amatol and fitted with either a No. 101 percussion fuze or a No. 106 direct action percussion fuze. The difference between the two fuzes was that the No. 106 was far more sensitive and could be detonated reliably on impact with soft ground or even barbed wire.

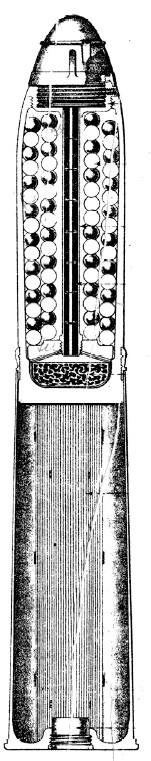

The shrapnel shell was filled with 375 lead/antimony balls and fitted with a No. 80 time &  percussion fuze. The fuze could be set to provide a time delay of up to 22 time units by rotating a time ring. When fired, the time pellet in the nose of the fuze was driven against a needle setting it off that, in turn, ignited a gunpowder trail whose length was determined by the time delay setting. When this burned through, it ignited the powder in the base of the fuze that then ignited the powder in a central tube connecting it to a bursting charge in the base of the shell. When this ignited, it blew off the fuze and propelled the shrapnel balls at high speed out of the front of the shell spraying the ground ahead of the shell. The fuze was also fitted with a percussion pellet that detonated the shell if it hit the ground before the time fuze burned through.

percussion fuze. The fuze could be set to provide a time delay of up to 22 time units by rotating a time ring. When fired, the time pellet in the nose of the fuze was driven against a needle setting it off that, in turn, ignited a gunpowder trail whose length was determined by the time delay setting. When this burned through, it ignited the powder in the base of the fuze that then ignited the powder in a central tube connecting it to a bursting charge in the base of the shell. When this ignited, it blew off the fuze and propelled the shrapnel balls at high speed out of the front of the shell spraying the ground ahead of the shell. The fuze was also fitted with a percussion pellet that detonated the shell if it hit the ground before the time fuze burned through.

The smoke shell was filled with phosphorus inside a tin plate container. The shell was fitted with a No. 106 fuze that detonated a small bursting charge on impact that blew off the separate steel base of the shell ejecting the contents. The phosphorus then ignited on the ground forming thick clouds of smoke.

The star shell was used to illuminate parts of the battlefield. It was fitted with a No. 180 time fuze (basically, a No. 80 fuze with the percussion detonator) and contained a bursting charge, a star composition and a parachute. When the small bursting charge was set off by the time fuze, it ignited the star composition and at the same time created enough internal pressure to shear the pins holding the base of the shell forcing out the contents. The burning star composition then descended slowly on the end of the parachute.

Later in WW1, shells were developed to dispense gas. These shells were similar to the shrapnel shells but fitted with a N0. 106 percussion fuze to set off the bursting charge when the shell hit the ground which, in turn, released the gas. The shells were coloured gray with a coloured band to indicate the type of gas.

18-Pdr QF Gun Mk I & II Specifications

- Length: 13 ft 8 in

- Maximum Width: 6 ft 3 in

- Wheels: 4 ft 8 in

- Weight of Gun & Carriage: 24 cwt 3 qr 21 lb

- Weight of Carriage & Limber: 40 cwt 3 qr 16 lb

- Length of Gun Barrel: 8 ft 1 in

- Length of Bore: 7 ft 8 in

- Bore: 3.3 in (84 mm)

- Weight of Gun & Breech: 9 cwt

- Muzzle Velocity: 1615 fps

- Maximum Range: 6525 yd

- Trail: Single pole

- Recoil System: hydro-spring (Mk I); hydro-pneumatic (Mk II)

- Maximum Recoil: 41 inch

- Rifling: Polygroove with modified plain section

- Length of Rifling: 6 ft 8 in

- Twist: Right-hand twist with 1 turn in 30 calibres

- Grooves: 18

- Firing Method: Percussion

- Elevation: -5° to +16°

- Traverse: -4.5° left to +4.5° right

QF 18-Pdr Mk III & IV Specifications

-

- Length: 13 ft 8 in

- Maximum Width: 6 ft 3 in

- Wheels: 4 ft 8 in

- Weight of Gun & Carriage: 29 cwt 0 lb 2 lb Mk III

- Weight of Carriage & Limber: 43 cwt 1 qr 25 lb Mk III

- Length of Gun Barrel: 8 ft 1 in

- Length of Bore: 7 ft 8 in

- Bore: 3.3 in (84 mm)

- Weight of Gun & Breech: 9 cwt

- Muzzle Velocity: 1635 fps

- Maximum Range: 9100 yd (Mk III); 9500 yd (Mk III* & IV)

- Trail: Box

- Recoil System: hydro-pneumatic

- Maximum Recoil: 48 inch

- Rifling: Polygroove with modified plain section

- Length of Rifling: 6 ft 8 in

- Twist: Right-hand twist with 1 turn in 30 calibres

- Grooves: 18

- Firing Method: Percussion

- Elevation: -5° to +30° (Mk III); -5° to +37° (Mk III* & IV)

- Traverse: -4.5° left to +4.5° right

![]()