Time and Percussion Fuze No. 80

The No. 80 time and percussion fuze was an based on an igniferous (combustible) fuze design by the German armament firm Krupp and built under licence by Vickers.

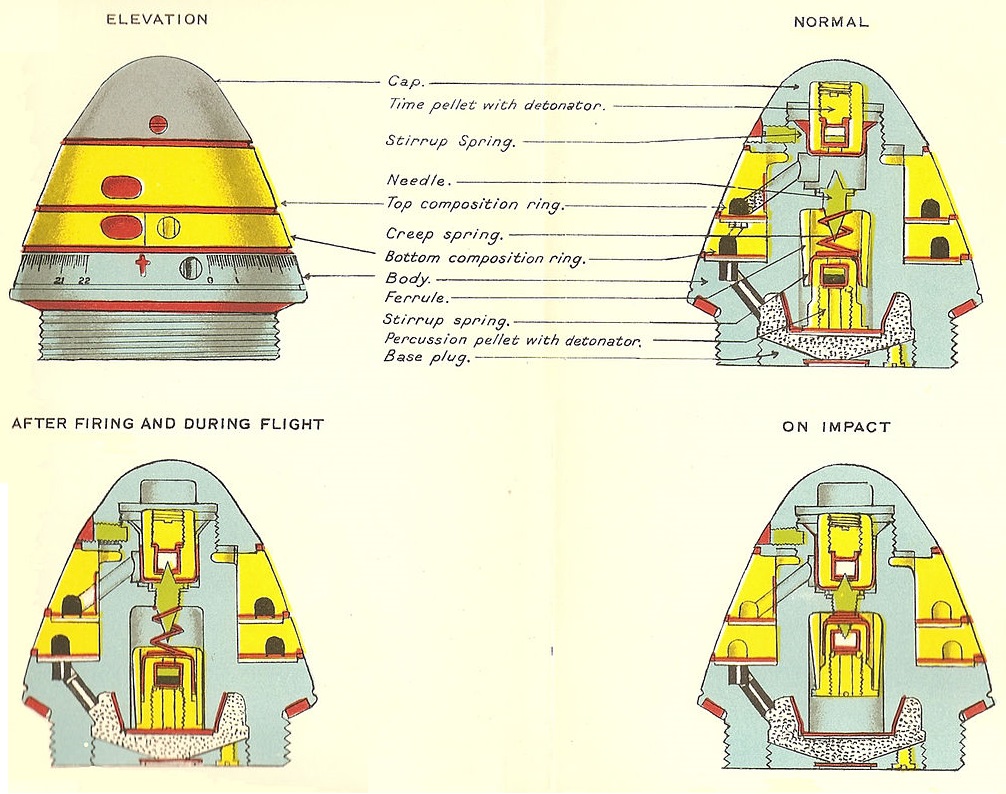

The fuze was designed to provide either a time delay of up to 22 seconds or an instantaneous detonation after hitting a solid object, normally the ground. The fuze therefore incorporated two separate detonator pellets; the time pellet under the nose cap for initiating the delay action and the percussion pellet in the base of the fuze for initiating the instantaneous action.

The time delay function is achieved by gunpowder trains in the fixed top composition ring and the rotating bottom composition ring. These trains are about 11 cm and 13 cm, respectively, and burn at just over 1 cm per second to give a maximum burn time of 22 seconds. The total gunpowder trainthat has to burn before the powder charge in the base of the fuze is set off is determined by the setting of the bottom composition ring. As seen from above,

The time pellet was initially held in place clear of the detonating needle by a stirrup spring. However, when the shell was fired, the shock generated overcame the force of the spring and the pellet was then driven into the needle to set off the detonator in the pellet. The flash from this then travelled down the gallery connecting it to the start of the gunpowder train in the top composition ring. When this had burned along the set train in both the top and bottom composition rings, it then ignited the powder in the gallery connecting to powder in the base of the fuze. This in turn ignited the powder train in the shell itself.

In the case that the time fuze did not activate, the percussion fuze in the base would set off the shell when it hit the ground. In the case of the percussion fuze, a safety measure had to be built in to avoid the shell being detonated accidentally; for example, by being dropped point fuze first on to the ground. This was achieved using an inertia device or ferrule in combination with a stirrup spring. Before firing, the ferrule in combination with the stirrup spring held the percussion pellet clear of the detonating needle as shown. However, when the shell was fired, the shock drove the ferrule downwards to overcome the stirrup spring effectively fixing it in place around the percussion pellet with the creep spring keeping it clear of the detonating needle. On hitting the ground, the deceleration would then force the pellet against the needle, detonating it along with the shell.

The time pellet was not fitted with the same type of safety feature because the risk of accidentally setting it off was much less than for the percussion pellet. Instead, the safety feature used was to rotate the bottom composition ring so that its index line aligned with the cross on the timescale, In this configuration, although the powder train in the top composition ring could be ignited accidentally in principle by dropping the fuze, it was impossible for this to spread to the powder train in the bottom composition because its input passageway was effectively blanked off. While the fuze was being transported, a tape was soldered on to the base of the fuze and held in place by a ring over the end of the fuze that held the bottom composition ring aligned with the safety cross. At worst, therefore, if the time pellet was accidentally set off, the top powder train would burn out but the bottom powder train and powder in the base of eh shell would not be. A burnt out powder train would be indicated by the upper blow off panel being missing.

![]()